Loading and unloading of catalyst in reactors

Loading and unloading of catalyst in reactors. Catalysts are substances that accelerate a chemical reaction, but without being consumed during it. The catalyst normally remains chemically unchanged at the end of the reaction. Many catalysts are complex mixtures of different chemicals.

In oil and petroleum refineries, this type of reactor is very common because it helps to accelerate chemical reactions involving hydrocarbon distillation.

Basic types ofcatalysts

The reagents and catalyst are in the same phase, usually in solution. The catalyst is generally recovered from the final product stream by a process such as distillation. Often, the raw catalyst material is supplied in powder form and the catalyst needs to be dissolved in an appropriate solvent before it can be used.

Heterogeneous – Reagents are usually in the liquid or gaseous phase and the catalyst is usually in the solid phase. The beans can be spherical, cylindrical or random in shape. Many heterogeneous catalysts can be chemically complex compounds. They typically consist of several main components suspended in an inert support material, such as aluminum oxide or silica. When these solid catalysts are manipulated, they can generate dust (aerosols) that is carried by the air and therefore can present a risk when inhaled.

Many substances used in catalysts can have dangerous properties when inhaled and are linked to several health problems.

The best way to guarantee the safety of workers when handling these materials is to know the MSDS of these products. The MSDS provided by the manufacturer contains details on handling, transportation and risk management measures, such as personal protective equipment (PPE).

In addition to new catalysts, the catalysts used may also include hazardous substances. These include residues of substances that remain in the catalyst due to the flow of materials that passed through them during chemical reactions, such as hydrocarbons and other products that were formed during catalysis.

These aerosols can penetrate the upper respiratory system or even reach the pulmonary alveoli and trigger chronic diseases and irreparable sequelae. Some substances in catalysts can cause serious adverse health effects if the catalyst is not handled properly.

Generally, these hazardous substances can be grouped into the following categories:

Residual Substances – Chemicals that remain in the flow processed by the catalyst. Depending on the application, substances such as benzene, butadiene or ethylene oxide.

Incidental substances – Probably the most worrisome are metallic carbonyls. Substances like nickel carbonyl and vanadium carbonyl are some of the most toxic substances found in industrial processes.

Entry into confined spaces with catalysts (reactors)

The best way to avoid accidents and exposure to these materials would be not to need to enter these confined spaces, but if entry into these reactors is necessary, particularly in the case of atmospheres inerted with nitrogen or other potentially hazardous waste , suitable respiratory protective equipment should be used, such as an anti-panic helmet with air supply. In some cases, the air supply sent in accordance with NBR 12543: 2017 is already sufficient, other times it may be that one or more redundancy systems (emergency backup) may be required to meet the degree of risk involved in the activity.

Entry into an inertized reactor is a high-risk operation and strict procedures are required, including equipment, supervision and specific training and examinations with the professionals involved.

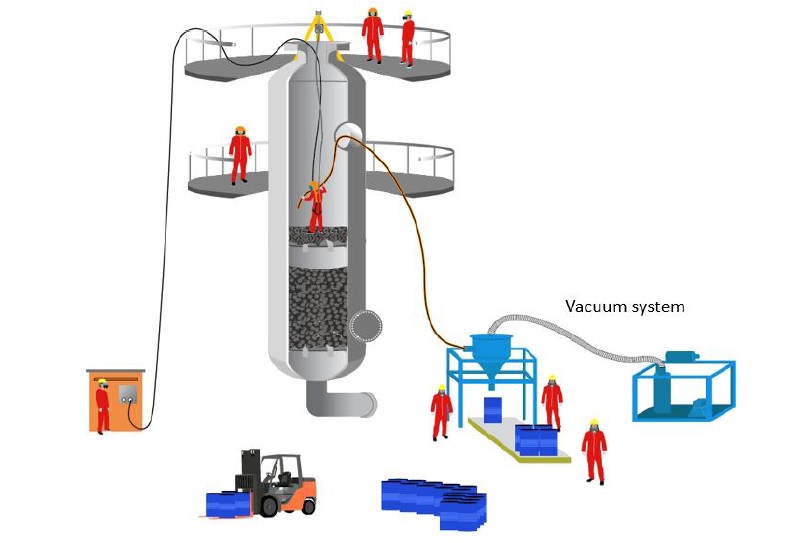

Unloading – Changing the Catalyst

Before a catalyst can be removed, the reactor must be completely isolated and purged of process fluids. Disposal of the catalyst must also be carried out properly, perhaps even more carefully than the charge due to contamination and spreading of this material in the atmosphere. There are many different reactor designs and the operation has to be adapted to the specific circumstances. Transport and disposal is also carried out very carefully due to the respiratory risks involved.

Vacuum unloading, on the other hand, requires pumps to properly suction and fill the packaging for disposal of the removed material. This type of discharge can minimize operator and environmental exposure by directly transferring the used catalyst to suitable drums. Even this type of disposal can cause friction between the catalyst and the reactor and cause the suspension of dangerous particles in the air. In some cases, the entry of workers into these reactors may be necessary.