Air Humidifier Grade D

Air Humidifier Grade D. Air humidifier or not. Air. It is advisable that the relative humidity of the air, for human breathing, is between 60 to 80%. Compressed air, used in adduction breathers, due to the physical process discussed in the initial items of this chapter, loses much of the moisture it had in the intake, causing the air that reaches the respirator to present extremely dry air, with relative humidity close 10% (see exercise below). This condition causes users a lot of discomfort, and for some, nasal bleeding. Lay people on the subject, think that they found the solution by purchasing “purifying” units, which include, as a marketing element, humidifier to “improve” air quality.

The compressed air generated in compression systems that do not have air dryers, but only condensate separators and coalescence filters is always saturated with moisture. This means that any amount of liquid water or steam added to the compressed air will not be incorporated, and therefore, it becomes a contaminant, no longer complying with the water requirement, for grade D air. water placed in the air by the “humidifier”, remaining in a liquid state, creates the risk of microorganisms developing inside the air supply hoses, and therefore, likely contamination by the user.

In order for the reader to understand the absurdity of trying to moisten the air in the area where he is still pressurized, and that he has not read the previous items in this chapter, it is convenient to follow the explanation presented below.

Compressed air generated by compressors and used in adduction breathers, in the vast majority of cases, operate below 1 Mpa (10 bar). The exercise below discusses a practical case, where the compressor pressure is 0.8 MPa (8 bar), and the user receives air saturated with steam because these units do not have an air dryer. After undergoing expansion in the flow regulator valve of the respirator, the expanded air, now at ambient pressure, has a relative humidity of 10%.

Measurements made by the authors of this Manual, in compressed air purification units with humidifiers, revealed that the relative humidity of the air rose from 10% (without water in the humidifier) to 30% with water in the humidifier. This increase occurs because liquid water that cannot be incorporated into the compressed air because it is saturated, when it passes through the flow regulating valve of the respirator, undergoes an instant evaporation and is incorporated into the air. It seems that the humidification system worked, except that the worker receives an additional charge of microorganisms that developed inside the hose as a “gift”.

Air humidification is only efficient if it is performed after the respirator flow regulating valve, which is close to the user, where the pressure is practically equal to atmospheric pressure. To reduce the discomfort of those who use an air adduction respirator, a good practice is to reduce the time of exposure to dry air, implanting the caster in the activity. Another alternative is to select, during the medical examination anamnesis, people with less sensitivity to the effects of dry air.

If the compressed air to be used is generated in systems that have purification units that include an air dryer, the use of a humidifier causes a negligible improvement in air humidity, since it would go from practically zero humidity (the dryer is precisely to dry the air!), to 8%.

If compressed air is supplied by a battery of high-pressure cylinders (200 bar, for example), it is practically dry (ppm), and if a humidifier was used after the 200 bar to 8 bar pressure reduction valve, the air would be able to incorporate only 1.44 g / kg of water, resulting in a relative humidity of only 8%, inside the respirator!

Exercise:

To carry out repairs to a tank, a company rented an oil-lubricated compressor for industrial use, powered by a diesel combustion engine. The compressor will supply air to the respirator of two welders. It is regulated to supply air at a pressure of 8 bar and 20 ° C. In the place of use the air is at 1 MPa (1 bar), and the ambient temperature is 20 ° C, with a relative humidity of 40%. Answer the following questions: 1) will it be necessary to use a coalescence filter? 2) what purification elements should the air purification unit have? 3) what will be the relative humidity of the air that will be provided to cover the user’s airway?

Solution

1) Is the coalescence filter necessary?

To select the purifying unit, it is advisable to check whether or not condensed water will form. For this, it is necessary to know the humidity of the air at the compressor inlet and outlet. Table 12.2 shows that the saturation humidity of the compressed air at 8 bar and 20 ° C is 1.8 g / kg dry air, and that the air entering the compressor has a RH of 40%. As the temperature is 20 ° C, water vapor = 17.5 mmHg, which is taken in equation 12.5, results:

pp water vapor = 7 mmHg, which taken in equation 12.4, results for the air entering the compressor U = 5 , 7 g / kg.

Therefore, at the air intake point of the compressor, the air humidity is 5.7 g / kg and at the compressor outlet, as much as possible 1.8 g / kg. They must condense 3.9 g of water per kg of air entering the compressor. A large part of this water will remain in the aftercooler, but the smallest drops will remain in the air, and in order for the air to comply with the “water” requirement for grade D breathing air, a coalescence filter must be installed.

2) What elements of purification and alarm are needed?

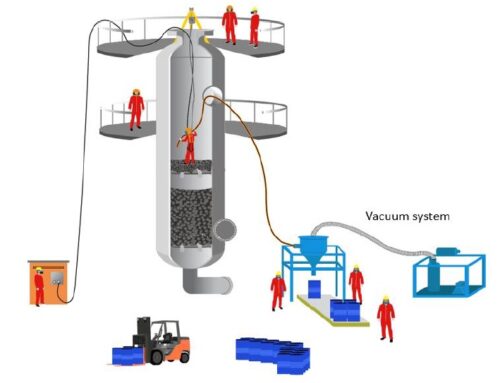

The purifying unit must have a pressure regulator to adjust the operating pressure of the adduction respirator with a filter for the retention of coarse particles from the line, a coalescence filter for the retention of micro drops of water and oil present in the air, an active carbon filter to retain the oil vapors that cause the smell in the air, monoxide detector for continuous monitoring of carbon monoxide, and alarm. In order to reduce the risk of carbon monoxide entering the compressor, the direction of the wind, the location of the air intake point that powers the compressor, and the exhaust duct of the engine combustion fumes must be considered. explosion.

3) What will be the relative humidity of the air inside the respirator

The air at the outlet of the coalescence filter is saturated with only 1.8 g / kg. When this air passes through the regulator valve of the airflow of the respirator, it will be at a pressure of 1 bar (760 mmHg), but with only 1.8 g / kg. This humidity, according to equation 12.4, will generate in the air a water vapor vapor = 1.44 mmHg. The relative humidity of the air that the user will breathe can be calculated by equation 12.5, by making water vapor at 20 ° C = 17.5 mmHg, resulting in UR = 8.2%

Note: Tables 12.2, Formulas 12.4, 12.5 have been deliberately omitted. The complete content can be obtained through the book by Professors Torloni (now deceased) and Vladimir Vieira.