Breathing Air Standards in European Community

The one of breathing air Standards in European Community, the European standard 529: 2005 is the central document that encompasses principles, guidelines, and measures of safety at work concerning the respiratory protection of any worker. It is equivalent to the British standard, so it has a very high degree of importance, being respected and followed by hundreds of thousands of professionals and employers in Europe.

Respiratory protection devices are classified into two types, according to the European community standard; filtering and breathing apparatus. The first ones can purify the ambient air through effective filters that remove harmful agents. The seconds allow users to obtain clean and breathable air, or even compressed oxygen gas, from non-contaminated sources. Thus, complete respiratory protection equipment consists of either a face shield and filters or a face shield and a means of obtaining breathable air or gas for the health and well-being of employees.

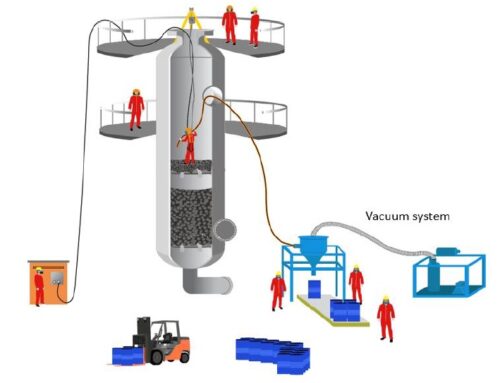

The 529: 2005 standard points out that there is an infinity of facial protections to attend to the most diverse contexts. These guards can fall into one of three categories: guards closest to the face, looser guards, and mouth guards. The first can be filter protections, masks that cover the mouth and nose, masks that cover half the face and that cover the entire face. Looser protections fit into hoods, helmets, visors, blouses, specific clothing. These provide sufficient air to prevent the proliferation of bacteria or other harmful substances close to the user. Mouthguards, on the other hand, must be used with other devices, since they make it impossible for the user to communicate with other people around them. What can be considered a breathable air or gas supply source for apparatuses and garments can be a chemical oxygen generator, a compressed airline, or even a vessel like a gas cylinder that will supply uncontaminated air or gas to a certain apparatus. Filters chosen for use in unhealthy environments need to be fully compatible with the substances they will protect their users from, given their factory limitations.

They can protect against particles (particle filters); gases/vapors (gas filters) and particles and gases/vapors (combined filters). According to EN 12021, a standard that regulates compressed air guidelines, the oxygen levels in the work environment must be around (21 ± 1)% per volume of dry air. The general compressed air for the breathing apparatus must not contain harmful substances in a concentration that may cause toxic effects to the body. In any situation, these levels must be below the national exposure limit.

The lubricant content (droplets and fog) must not exceed 0.5 mg / m3. As for odor and taste, the air cannot contain any of these elements. Carbon dioxide must not exceed 500 ml / m3 (500 ppm) and carbon monoxide must remain low, but it cannot exceed 15 ml / m3 (15 ppm). The air for the compressed air breathing apparatus must have a dew point low enough to prevent condensation and freezing. When breathing air is used or stored in an area where the ambient temperature is known, the pressure must be at least -5 ° C compared to the lowest temperature considered. But when it cannot be predicted, this value should not exceed -11 ° C.

The sufficiency of air supplies for breathing should be checked using periodic tests. The volume, flow, and quality of compressed breathing air must be tested at least every 3 months or whenever a compressor is moved as the internal air is being drawn from a new location. A detailed air quality test needs to be designed and reviewed by a trained professional to verify suitability for the purposes intended for use. This should be done in conjunction with the compression and air purification services, in addition to maintenance reports, to provide a complete overview of the installation.

The EN 137 standard, which standardizes respiratory protection equipment guidelines, mentions that a suitable apparatus includes pressure vessels and body protections, demand valves aimed at the lungs, pressure indicators, warning devices, connection hoses, tubes, and protective masks. full face. You can also include pressure reducers, additional air supplies, ambient air devices, etc. This allows the user to breathe compressed air on demand. The exhaled air then passes without recirculation to the ambient atmosphere.