Risks of silicosis

Risks of silicosis. Silica is silicon dioxide, whose chemical formula is SiO2. SiO2 is the most abundant mineral on earth, it includes a large part of sandstone, granite and slate, sand in general and almost every type of rock. Silicosis is a lung disease caused by inhaling fine silica dust, the dust causes inflammation and scarring of the lungs. The scar appears on the chest X-ray. Silicosis is a type of pneumoconiosis, the medical term for lung cancer caused by scarring from inhaled dust. Pneumoconiosis can also occur from inhaled asbestos (asbestosis), coal (coal miners’ pneumoconiosis), and other breathable dust. There is no effective treatment for any type of pneumoconiosis, including silicosis.

Diagnosis of silicosis:

* Abnormal chest X-rays (or chest computed tomography) consistent with silicosis

* History of significant exposure to silica dust

* Medical evaluation to exclude other possible causes of abnormal chest using X-rays

* Pulmonary function tests are useful for assessing the severity of the deficiency, but not for diagnosis.

* Lung biopsy is rarely indicated (since no effective treatment, biopsy is done only when other diagnoses are being considered).

Risks of silicosis. Silica dust

Silica is a common, naturally occurring crystal. Found in harder rocks, it forms fine dust during mining, quarrying, tunnel construction and drilling. Silica is the main component of sand, so workers in the manufacture of glass, sand, engineers, technicians and employees who have some contact with the dust produced by handling different types of rock exploration may also be overexposed to this type of aerodipersoid. Occupational exposure occurs through the inhalation by the worker of dust containing crystallized free silica.

Dust

All dust, solid particles of any size, nature or origin, formed by crushing or other mechanical rupture of a solid original material, suspended or able to remain suspended in the air. These particles generally have irregular shapes and are larger than 0.5.

The location of the deposition of particles in the human respiratory system depends directly on the size of the particles:

– inhalable particles – particles smaller than 100 µm, are able to penetrate through the nose and mouth;

– thoracic – particles smaller than 25 μm, are able to penetrate beyond the larynx;

– breathable – particles smaller than 10 µm, are able to penetrate the alveolar region.

Risks of silicosis. Exposure to Silica Dust – Risk Factors

Any work that exposes to silica dust:

* Mining

* Cutting stones and rocks

* Mineral extraction

* Road construction and civil construction

* Working with abrasive products

* Glass making

* Sand blasting

* In addition In addition, some hobbies may involve exposure to silica (sculptor, glass blower)

* Coal Mines

* Foundry

* Metallurgical, Steel

Prevention – How can silicosis be prevented?

Replacing the silica which consists of using a different, safer material in place of the silica-containing substance. It is true that in some cases it is not possible to use a substitute in place of silica, but for many operations, such as blasting there are many possible substitutes , including those cited below:

* Aluminum Oxide

* Hydro Jetting at high pressures (40,000 psi)

* Glass microspheresSteel grit

** Aluminum oxide

* Abrasive blasting with CO2

* Ceramic abrasives (made from mineral oxides by electro fusion )

* Plastic abrasives (UREA, ACRYLIC, POLYESTER and MELAMINE)

* Sodium bicarbonate.

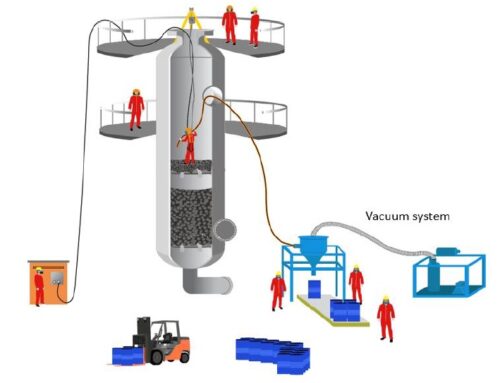

Engineering controls – Keep silica off the air

If silica products are to be used, engineering controls to be used whenever possible This type of control involves a mechanical process to eliminate exposure to silica dust Some of these controls can be very simple , as can be seen in the examples below:

Install a water hose to wet the dust at the time of generation

Install local exhaust fan

During rock drilling, water flow through the drill rod

Install dust collection systems on machines or equipment that generate dust

Use concrete / masonry saws that provide water for the blade

Work practices: What can employees do to reduce silica consumption?

If workers know about silica and understand the severity of its health hazards, they will be more likely to do the following:

Know what work operations can lead to exposure to silica

Participate in all air or air monitoring programs training offered by the employer

If possible, switch to disposable work clothes or washable at the workplace; shower (when available) and change into clean clothes before leaving the workplace.

Do not eat, drink, use tobacco, products or apply cosmetics in areas where there is dust containing crystalline silica.

Wash your hands and face before eating, drinking, smoking or applying cosmetics outside the exhibition area.

If using respirators, do not change the respirator in any way.

Use CE positive pressure type abrasive blasting blowers for blasting

For other operations where respirators are required, use an approved respirator to protect against crystalline silica containing dust.

If wearing tight masks do not grow a beard or mustaches.