Risks of ionizing particles. Respiratory Protection against Contamination by Ionizing Particles

Risks of ionizing particles. With the discovery of the principles of nuclear energy, several fields of science have developed. Radiotherapy, X-rays, the use of radiography in agriculture, gammagraphy in industry, fossil carbon dating 14 and the generation of electricity are some of these applications. The growth of these large-scale applications and the ever greater manipulation of such a principle has brought with it some serious and difficult problems to be solved or circumvented.

Contamination of the environment and living beings is one of these problems. In this article I bring you some relevant information regarding the risks and the precautions that must be taken inside nuclear plants, uranium enrichment factories, subsidiaries and other activities that in one way or another end up having direct contact with materials that may be contaminated with particles ionizing. Our focus, as always, will be respiratory protection and the technologies involved to ensure the health of those who come to manipulate such sources of contamination.

Contamination x Nuclear Radiation

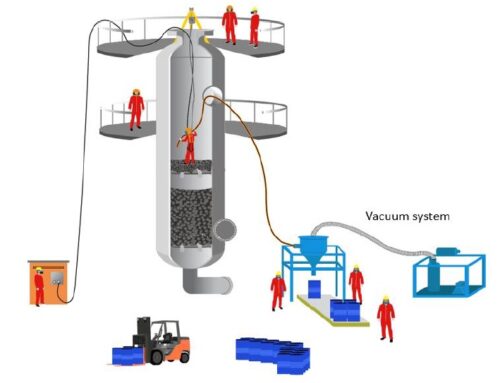

Imagine the simple task of cleaning and cleaning an industrial building. A common cleaning, cleaning the floor, walls, parts and cabinets. Imagine? It’s not difficult is it? Yes, but this task can be very difficult and require technical resources, planning and specific procedures when we are in a nuclear power plant.

Before starting properly with respiratory protection against ionizing particles, it is necessary to define at least a definition of contamination by radioisotopes and the radiation emitted by these materials. Contamination by radioisotopes occurs when any surface or person has contact with water, aero dispersoids or any other type of material that contains atoms emitting ionizing energy. When this occurs, the contaminated surface becomes a source of radiation.

Nuclear radiation happens to any particle that carries radioactive atoms. The emission of this form of electromagnetic energy is capable of causing changes in the genetic material, malformation of cells, burns and can lead to death when the absorbed radiation doses are very high.

The concern of the safety, occupational health and environment departments of the companies that handle such materials is to avoid at all costs, leaks, dispersion of contaminated material, generation of contaminated waste (radioactive waste) and the radiation doses absorbed by employees as small as possible while they are on the company’s premises.

Risks of ionizing particles – Contamination

Contamination of the human organism by uncontrolled radioactive sources is very complicated, because generally these particles are very small and can hide or be absorbed into the cells. As the contaminated particle is a source of ionizing energy, within the organism such a particle will surely trigger changes in the genetic material and produce harmful effects in the medium and long term. Working with certain radioactive materials, such as volatile I-125 or millicurie quantities of S-35 methionine / cysteine, must be handled on benches with hoods to suck up all volatilized material to avoid inhalation by workers. Tritium (gas), for example, has a high diffusivity and requires special care to prevent its ingestion, inhalation or absorption through the skin.

When working with radioactive material, clothing should isolate the entire body from possible contacts, splashes and spills. Respiratory protection in environments with the possibility of dispersion of ionizing particles or even routine work that manipulates such materials are special cases of occupational health and safety in companies. The nuclear plants of Angra I and Angra II, for example, have a radiological protection department that takes care of controlling permissions, accesses and occupational dosages received by everyone who accesses the controlled areas and also takes care of cleaning, monitoring of incoming and outgoing material. of the plant.

In maintenance workshops or industrial maintenance stops the use of respiratory protection occurs in specific jobs, where the suspension of particulates (aero dispersoids) can in some way compromise the health of workers in the medium or long term due to the cumulative effect on the body, or even due to the presence of toxic gases that can cause accidents or even death from asphyxiation or poisoning. However, in the maintenance activities that take place in the buildings or in the sectors of the nuclear plant, when for some reason there is direct contact with the primary circuit of the power generation process, the probability of having contact with ionizing particles is high. The simple task of inspecting steam generators (GV) or even cleaning the system’s water circulation pumps can compromise the respiratory tract and even reach the circulatory system. Now imagine a particle contaminated with highly radioactive atoms inside the cells? It doesn’t look good does it?

Some tasks have such high probabilities of contact with radioactive material by operators, that inflatable coveralls, popularly known as blisters, are used. These are transparent material garments that protect the whole body against particulate contamination, ionizing vapors and splashes, due to the type of material that is produced and the positive pressure generated inside the garment. Some are made of material that prevents part of the radiation from penetrating the material. Some others are ventilated and may even have air flow regulation in the inlet coupling of the supplied air hose (breathable air). Generally speaking, they are designed to be easy to remove and are disposable. Such personal protective equipment is used only in activities where it is really necessary for human contact with some contaminated material, due to the risks of this activity.