OSHA Respiratory Protection Standard

OSHA Respiratory Protection Standard. 29 CFR 1910.134. The quality requirement for breathable air provided by breathing equipment is often one of the least understood elements of a respiratory protection program. Air supply respirators (SAR) [1] and Self-Breathing Apparatus (containedSCBA)[2] are subject to very similar air quality requirements.

Although the need to provide a source of “clean” air is obvious, there are unknowns unanswered by the standard and this makes some questions and requirements ambiguous. The purpose of this article is to shed some light on the subject of “breathable air specifications” and to present some possible ways to ensure that the standard is met.

Air quality specifications – OSHA 29 CFR 1910.134

According to OSHA (Occupational Safety & Health Administration), air compressed breathable must meet at least the requirements for Type 1 – Degree of air respiration D described in ANSI / CGA G- 7.1-1989:

OSHA Respiratory Protection Standard

- Oxygen: 19.5-23.5%

- content Hydrocarbon(condensate) of 5mg / m3 of air or less

- CO content of 10 parts per million (ppm) or less

- content CO2of 1,000 ppm or less

- Without noticeable odor Breathing

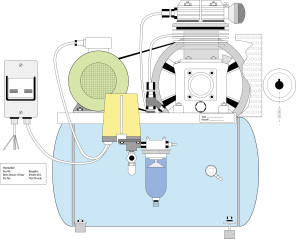

Air supply compressors for respirators must be equipped with suitable air purifiers in the air lines, and adsorbent bed filters that are maintained and replaced or renewed according to the manufacturer’s instructions. For non-lubricated compressors, the levels in the air, the breath should not exceed 10 ppm.

For oil-lubricated compressors, high temperature alarm CO, or both, must be used to monitor levels. If only high temperature alarms are used, the air supply must be monitored at sufficient intervals to avoid levels GO above 10 ppm The dew point must be 10 ° C below the lowest expected temperature or -29 ° C (400 PPM at 760 mmHg).

The standard makes clear all the parameters that the breathing air source must present, but does not say how these parameters must be obeyed. It does not deal with monitoring or air treatment equipment and the way they are supposed to work. It is not even specified how often this parameter monitoring should be performed.

The standard understands that there is no way to create a standard that meets all customers or all possible applications and therefore it is up to each manufacturer to specify the frequency with which the breathable air filter elements, co catalysts, compressor filters , room air intake filters, air conditioning or treatment devices are replaced. For example, the standard says that the air must be odor free, but how should this be obeyed since the sensitivity of each person varies a lot in relation to each possible odor, not to mention the infinity of gases and varying concentrations that it can affect one person more than another.

The following is transcribed item 1910.134 (i) of the United States Department of Labor – OSHA (Occupational Safety & Health Administration). It is the response of Richard E. Fairfax, Director of the OSHA Compliance Program for breathing air issues Grade D to a question asked by a professional in the field. See what he says in relation to the monitoring of breathing air:

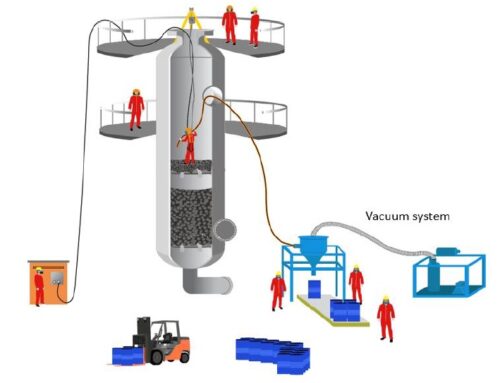

So, what is concluded is that in case of cylinder refill SCBAequipment, breathing air generation equipment through portable compressors or cascade systems, which is the norm it requires a point measurement to be made and, in the place where the air intake will be carried out. The standard does not highlight whether a fixed monitoring system should be maintained throughout the operating time for any variable in the breathing air. It is advised, only, that the operator or user of the equipment should position the equipment in a way that prevents or minimizes the chances of catching contaminated air if the atmosphere where the equipment is present is contaminated.

This type of approach does not cover a gap with respect to variations in the atmosphere over the time the equipment is energized. Take as an example a truck with an internal combustion engine powered by diesel oil, located near the air intake of this portable equipment, or a forklift powered by LPG (liquefied petroleum gas), a cloud of gases produced by the combustion of these engines it can contaminate the portable breathing air source with carbon monoxide or even cause the oxygen level to drop to worrying levels and cause even the death of operators.

Therefore, some applications have taken these risks into account and adopted the use of fixed meters / detectors close to the capture of this equipment. Thus, on the one hand, the standard is met, since every time the equipment is to be used, monitoring is carried out over time and on the other hand, it prevents the compressor from capturing contaminated air when it is in use at any time. . Also as part of preventive planning for this type of problem, some industries use the use of windsocks and anemometers in their plants to better predict and avoid accidents with leaks of toxic or asphyxiating gases and vapors.

[1] SAR (Air Supply Respirators): Represents one of the highest levels of protection that users can use. They are designed to continually provide you with a D degree of breathing. They are usually connected to a compressor and / or cascade system. Generally, this type of equipment is operated remotely and does not depend on the user’s performance.

[2] Self-breathing apparatus (containedSCBA), an air supply respirator for which the source of breathable air is designed to be transported by the user.