Mobile breathable air

Mobile breathable air. The mobile breathable air unit is a system created to supply air sent to workers who need respiratory protection equipment such as air adduction respirators – compressed air line respirators (to learn more click here).

Mobile breathable air – Breathe mobile air unit

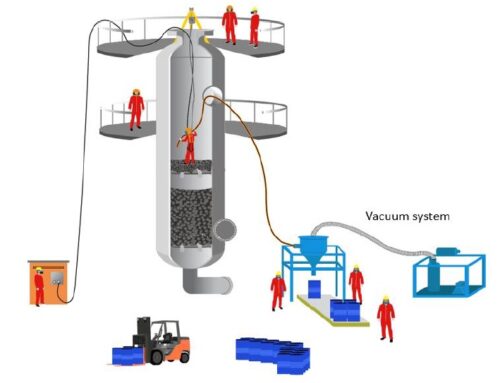

These dedicated systems are created to generate, filter and control the air quality that will supply workers’ masks with all the mobility of a trailer. They are basically composed of: air compressor, compressed air dryers, air filters to retain particulates and oil condensates,breathable air filters(purifiers), multi-gas detector and a backup system (redundancy or security system) capable of supplying the compressed air line for breathing in case of any problem with the compressor or there is a gas cloud in the capitation or in the outlet. This air backup can be done with batteries of compressed air cylinders stored at high pressure, where the pressure is regulated to meet the demand for low pressure air for workers’ EPRs.

The mobile breathing air unit is one of the types of adduction air breathers together with stand-alone sets (know what this ishere),compressed air cylinder batteries and natural air respirators. This type of respiratory protective equipment (EPR) is used where the worker cannot inhale the air from the work environment. These are situations with little or no oxygen, situations where there may be no air renewal, environments with the presence or possibility of gas formation, environments highly loaded with dust and air dispersoid of all kinds (Download Gravacentro Fundacentro Analysis), environment with biological and nuclear risks or chemicals.

Any environment that is hostile to the health and life of the worker who needs to use a breathing air source external to the work environment (adduction air respirators) can benefit from the features of the mobile breathing air unit. Especially when the volume of air consumed by workers is high and the time required for tasks is undefined or may vary, this type of system is an excellent option.

Why use the mobile breathing air unit?

Advantages of the mobile breathing air unit:

· Unlimited air reserves.

· Large flow / volume of air generated.

· Highest level of security for robust and fail-safe backup systems.

· Precise control of the technical characteristics of the air and gas concentrations.

· Easy system operation and control.

· The cost of generated breathing air can be up to 80% cheaper than renting cylinders for the same purpose

· Relatively high investment compared to other breathing air systems.

· Weight and volume relatively higher than a stand-alone set or battery of cylinders.

· Must be towed with a car.

· Unviable for small areas (eg oil platforms – offshore).

· Special projects – handmade and custom production.

Disadvantages of the mobile breathing air unit

· Relatively high investment compared to other breathing air systems.

· Weight and volume relatively higher than a stand-alone set or battery of cylinders.

· Must be towed with a car.

· Unviable for small areas (eg oil platforms – offshore).

· Special projects – handmade and custom production.

Mobile Breathable Air Unit Alarms and Alerts

The mobile breathable air unit must have at least one audible alarm and another high intensity and visual alarm that should inform workers about the lack of air in the system or even when any situation that may occur risk to users. It is common for the alarm system to go off when backup reserves are compromised during use or exhausted when the equipment is turned on.

As they are hybrid and special systems, the mobile breathing air unit usually brings the concepts of safety and reliability of other EPR standards, such as the standards for masks, pressure regulators and accessories in addition to the concepts brought in hospital medical standards (learn more here DC50 – medical gases).

Generally, these systems have gas detectors to monitor the concentration of carbon monoxide (CO) and oxygen rates (O2), according to the standardABNT NBR 12543. More advanced ones, in addition to monitoring these variables are able to monitor the concentrations of oil mist (volatile hydrocarbons- VOC), carbon dioxide (CO2),dew point(PO), hydrogen sulfide(H2S),chlorine(Cl2 ), ammonia (NH3) and the temperature of the air source.

Some applications of the mobile breathing air unit

· Work in confined spaces(welding, painting, surface treatment, cleaning, blasting).

· Work in IDLH atmosphere.

· Works in inert atmospheres (withnitrogen N2, for example).

· Handling of biological and hospital material contaminated with microorganisms.

· Industrial cleaning of tanks, reactors, exchangers and heat exchangers.

· Cleaning of food and chemical silos.

· Handling, storage and transportation of cement, wood, glass and carbon black.

· Cleaning, inspection, handling and compacting of radioactive or contaminated material.

· Works in sewage galleries, click here to know more about it.

· Drilling, cutting, dismantling, crushing, sifting and handling(rocks asbestos) and siliceous (silica and silicosis Fundacentro) in mines and process units.

· Handling of raw materials and pharmaceutical products containing: antibiotics, antiretrovirals, cytotoxic substances and hormones.