Continuous carbon monoxide monitor CO and alarm

Continuous carbon monoxide monitor CO and alarm. “Compressor Lubricating oil should use a high-temperature alarm or CO alarm, or both.” However, in the Technical Report of NIOSH, presented in Appendix F “breathing air systems for use in positive pressure respirators in asbestos abatement works” (9), the author of the report recommends, based on studies carried out on compressor overheating, which the monitoring of the CO should be prioritized and not the high-temperature alarm, as it can be read: “carbon monoxide monitor and alarm must be installed and working in the breathable air that leaves the breathable compression system.”

The Protection Program respiratory Fundacentro (PPR), 4th review-. 2016, says the same thing in every application that you use air compressed industrial (lubricated or not) should use a conntínuo CO monitor airline.

manufacturers use two basic types of CO monitor: one that is specific to CO and will ignore the presence of other chemical agents and only alarm in the presence of CO (selective sensor, electrochemical for example) and another, non-specific type, which accuses the presence of certain gases, including CO (non-selective sensor – semiconductor pe).

The use of a non-specific sensor may be more alarming than if the specific sensor was used. The selling point is that other hazardous gases may be present in the ambient air trapped by the compressor. The occurrence of frequent alarms interrupts the work and this can significantly increase costs and impair the completion of work and the reliability of the system over time. Turning off the alarm in these circumstances is a very dangerous practice and MUST be avoided. The CO monitor must be kept calibrated, and every time it sounds, it is to be respected. When the alarm sounds and while it is sounding, samples should be taken in order to check for the presence or absence of CO. If frequent alarms occur, other substances that caused the event should be sought and eliminated.

If alarms continue despite efforts, seek help from the monitor manufacturer: either to obtain a new monitor of the same type to eliminate the possibility of electrical or mechanical defects, or to look for a monitor and alarm from a different manufacturer.

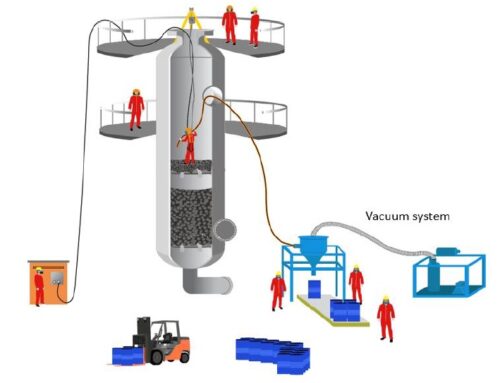

The CO monitor must be installed at the outlet of the air purification system. The monitor’s alarm signal can be visual or audible. When the visual alarm indicates the presence of CO, it must be confirmed by measurement and by the green/red light system. The audible signal, when present, must be audible in a place with high noise, and, for that, it must have a high sound pressure (80 to 90 dBA). The monitor can be adjusted to alarm at different concentration levels but for grade D air, it should not exceed 10 ppm.

Thinking of the New PPR, Breathe developed a monitor CO low cost for breathable air to adapt the filter stands and breathable air purifiers to the requirement of this.

Powered by mains (90 to 240VAC). It has LED bar graph indicating the levels of contamination of the network by carbon monoxide (CO). It also has a led that is flashing (in flash) to indicate activity and an Ok module and another led to indicate that the electrical network is Ok. It also has a sonar alarm (audible alarm) that is activated if the air network contamination exceeds 10 ppm. It has configurable relay outputs that can trigger an audible or visual alarm, enable a backup system (emergency cylinders) or even block an air supply network compromised by levels CO.

Consult Breathe’s Technical Department for more details on the CO Monitor for breathing air.