Coke oven gas

Coke oven gas is a manufactured gaseous fuel, rich in methane, hydrogen and carbon monoxide generally obtained from gasification by pyrolysis of coal and other mineral coals.

It can also be obtained by thermal or catalytic fractionation of petrochemical naphtha derived from oils or other carbon-rich materials, such as biomass and waste containing plastic materials. It was one of the first combustible gases made available for domestic use.

In the past, coke oven gas was produced in factories, located in the cities preferred to supply, in which the raw material was gasified, usually by pyrolysis, and the resulting gas was washed out of fumes and impurities. The gas was then compressed and stored in large tanks, usually with a floating roof (gasometers) and from there distributed to a primary distribution network.

Coke in metallurgy and coke gas

Metallurgical coke is mainly used in the iron and steel processing industry as blast furnaces, sintering plants and foundries, to reduce iron ore to iron. China is the world’s largest producer of metallurgical coke.

Thus, there are coals that are used to produce coke oven gas, steam or coke itself. Coke is an amorphous coal, resulting from the calcination of mineral coal widely used in the steel industry.

Composition of the coking plant gas

The composition of the coking plant gas varies depending on the raw material used, the production method and the washing operations to which the gas will be subjected. The values that follow are typical values of a gas to supply the city, technologically evolved and that is denoted by the low levels of nitrogen and carbon monoxide:

Hydrogen: 45.0%

Methane: 35%

Ethylene: 4%

Carbon monoxide : 8%

Carbon dioxide: 2%

Nitrogen: 5.5%

Oxygen: 0.5%

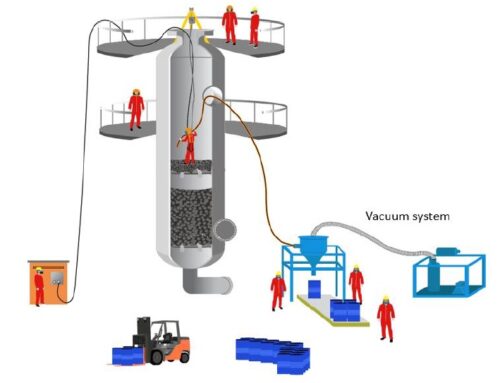

Work in blast furnaces / metal smelting

Due to the high temperatures involved in the metallurgy and steelmaking processes, the release of vapors and metal fumes is present constantly and can be easily inhaled and cause chronic and irreversible respiratory problems to workers. In addition to respiratory problems, the heat radiated by these tasks interferes with the performance of activities and can quickly dehydrate the body.

In these activities, the protection factor of respirators (mechanical, chemical or combined) may not be able to provide air with breathable quality, either due to the excessive effort provided by an atmosphere that compromises the life of the filters and as a consequence the quality of the tasks , whether due to the oxygen rates becoming compromised or due to the high temperatures, it is recommended air – with the parameters in accordance with blownNBR 12543to use, Grade D.

With the use of a properly dimensioned breathing air system, worker can perform his activities with more quality, safety and comfort. In these blast furnace jobs, the air can be cooled to reach the airways and this will add more quality and yield to production.

In blast furnace activities, the formation and release of CO and CO2 is constant and can easily reach the occupational exposure limits established by the standards (NBR 12543 / NR 15) and compromise the health and well-being of the worker.