Breathable air blasting

Breathable air blasting. Abrasive blasting or abrasive blasting or simply blasting is a surface treatment operation that consists of propelling a flow of abrasive material against a surface at high speed, in order to erode a surface, make a smooth surface rough, give shapes to a surface, remove contaminants from a contaminating surface or even hammer a metal surface.

The most widely used propellant is compressed air. Water (can also be used hydro jetting)- usually for maintenance and surface treatment of platform ships and oil and gas plants, and there is also underwater abrasive blasting, also used in FPSO ships and offshore pipelines.

As a method of surface preparation, sandblasting began to be used in the 1930s, having only become a standard method since the Second World War, when the American Navy concluded that painting a ship had a much longer durability if the surface was sandblasted.

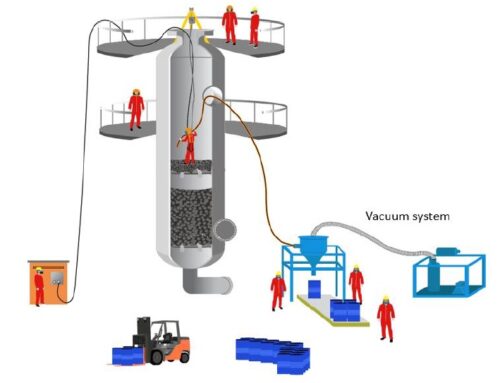

When working with a steel shot, suitable respiratory protection equipment, such as a helmet with an air line, is required to ensure that aerodispersites do not reach the worker’s airway. The standard that deals with respiratory protection for this activity isABNT NBR 14750 – Hooded compressed air respirator, for use in blasting operations – Specification. In some hydro jetting jobs, it may also be necessary to use blown air to ensure that air reaches the worker’s airways as breathing air standards require. And when jobs are done below the surface of the sea for more than an hour or two, divers sometimes use a supply of breathable air on the surface.

Companies must offer PPE suitable for blasting work, inform and ensure that everyone involved in the work knows occupational hazards. Workers directly involved in blasting must undergo training and qualification to carry out the work. In the USA,Hazard Communication Standard (29 CFR 1910.1200) OSHA ‘determines the standards and procedures for carrying out this work.

Continuous monitoring of mandatory CO

According to the new PPR from Fundacentro, for blasting operations, respirators for blasting operations (5.3), for blasting operations, respirators specifically approved for this purpose should be selected due to abrasion resistance. Blasting in confined spaces can generate levels of contamination that exceed the capacity of any respirator, requiring the adoption of 43 other control measures in order to decrease the FPMR below the FPA for that respirator. One should be aware of the mandatory use of compressed air of breathable quality with continuous monitoring of carbon monoxide (see item 11).