Non-toxic hoses for breathable air to air

Non-toxic hoses for breathable air to air. When it comes and sent air, little attention is paid to this accessory so important in this type of work. The breathing air hoses are responsible for transporting the treated breathing air from the air purifier to the workers’ masks.

The hoses for breathable air must be manufactured with non-toxic materials, resistant to heat, resistant to strangulation, folds and splashes of chemical products, must also be properly attached to the quick couplings in order to withstand traction and the large number of maneuvers that will be subjected during its useful life.

It is also worth remembering that the quick couplings for this type of work must be of the double safety lock type and with a different pattern to avoid connection with other gases.

They generally withstand temperatures ranging from -10 ° C to + 55 ° C.

This type of accessory consists of one side with a pin (male part of the connection) and the other side with a quick coupling (female), which is interchangeable and can be connected to each other and keeping the line always pressurized even when one side is disconnected from the compressed air network.

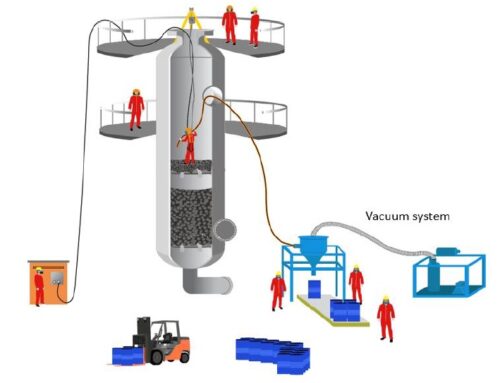

recommendation OSHA’s is that the total length of these breathable air hose strokes should not exceed 300 feet (90 meters) counting all strokes. The Fundacentro / MT also guides accordingly.

Non-toxic hose for linear breathable air

Generally when work is performed in confined space, cleaning tanks, blasting and painting these hoses are made of PVC with polyester wefts to increase the pressure and traction resistance during the work. The most widely used gauge for linear hoses is the 3/8 ”internal and the most used colors are: blue, yellow and black. The lengths most used for hoses for linear breathable air are: 5m, 10m, 20m, 30m and 50m. But there are special sizes such as 50m that in applications with long distances avoid great load losses in the couplings and possible leaks.

Non-toxic helical breathing airHelical breathing air

Hoses are generally used in the pharmaceutical industry and have the characteristics of retracting after use and can be stretched for up to 10m when necessary. This characteristic is important in applications where spaces are limited and the hygiene of the places is essential after activities. They are generally made of polyurethane (PU) and have standard sizes of: 2m, 5m, 10m and 20m. At the ends, they must also have quick couplings with double safety lock usually locked / pressed with steel washers in special presses for this. They are also used in paint booths, welding (but coated to prevent damage) and clean rooms. Generally, in this type of application with helical hoses, it is more common to use hoods for handling pharmaceutical chemicals and air helmets for welding, painting or sandblasting.