Grade D air filtering station Grade D air

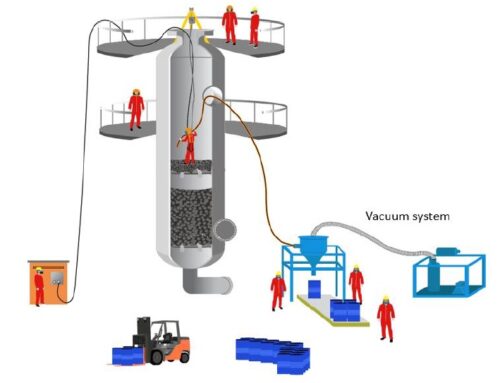

Grade D air filtering station Grade D air filtering station. During routine work in industrial environments, there is sometimes a need to use air sent in situations that pose a risk to workers. Confined spaces, unhealthy environments, inert atmospheres and atmospheres IDLH are constant challenges for the engineering and industrial security staff of companies. Often a given industry may have air lines sent close to the work fronts, however the quality of this air is generally not the best and, they can present all sorts of particulates, excessive amount of mineral oil, organic vapors, asphyxiating and toxic gases . These gases can cause the oxygen rate of the air source used to decrease and kill operators by suffocation. This article discusses the use of a portable air purifier – filtering station to fill a gap in the use of respiratory protection.

There is a portable purifier – filtering station that aggregates in the same equipment: pre-filters, filters, dehumidifiers, pressure regulating valves, and more importantly, they have oxygen meters and carbon monoxide detectors. These purifiers are no more than a meter in length and are generally light enough to be transported quickly from one work front to another by a single person. In addition, almost all have some kind of audible and / or visual alarm to alert the user to any abnormality in air quality. Very few have any type of recorder as a printer or interface with a notebook or capable of transmitting the purifier information wirelessly. Other even more sophisticated purifiers have an air line parallel to the air source, if there is an alarm that puts the professional’s life at risk, a battery of cylinders charged with compressed air, of reliable origin, is enabled and supplies the demand for air for some time.

Advantages and disadvantages of the portable purifier

This type of equipment brings mobility as an advantage, and relatively low cost when compared to an air system dedicated to the use of breathable air. Time is another relevant factor, since the implementation of a dedicated system for respiratory protection involves planning, engineering and other departments of the company and this brings some delay to any line of activity. On the one hand, unions, CIPA and other supervisory bodies concerned with the health of employees demand that the company take measures that guarantee the health of employees and, as every activity involves maintenance stops, downtime and “stopped” operators, therefore, portable purifiers present an investment to be studied.

One of the disadvantages is that the filters of this type of portable equipment usually saturate quickly due to everything that an airline of instruments can present of more unhealthy, oxidation of the pipe, detachment of oxidized iron, particulates, iron powder, oil mist and water condensate, and other products that can be accidentally injected into the compressed air tubing. Another factor that must be taken into account is that this type of equipment needs electrical energy to measure gas concentrations or, when powered by batteries, they must be kept charged to be used.

Before deciding on a portable purifier or a complete compressed air generation and treatment system as part of the employees’ respiratory protection solution, each company must take some questions into account, answer them and, if necessary, seek a professional specialized in the field of respiratory protection to help compose a solution.