Breathing air

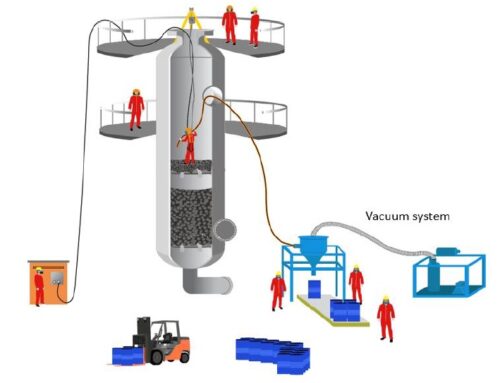

Breathing air filters. Work in confined spaces, IDLH atmospheres and highly contaminated environments with articulations are some activities that may need respiratory protection with the use of compressed air line respirators.

These respirators need a breathing air system, and one of the most important steps in these systems is breathing air filters. Sometimes these systems are so well dimensioned and implemented that they compare to medical air plants, but sometimes they are not. Therefore, the purpose of this article is to clarify the differences between a compressed air filter made in the manufacturing process and a filter dedicated to breathing air systems.

Breathing air filters are part of one of the most important stages of breathing air systems together with dryers and catalytic converters, but due attention is not always paid to them. Some professionals involved in respiratory protection believe that these filters are common filters for process compressed air, or that using filters to remove particulates and oil mist – for industrial applications – the system will be suitable for human breathing. The problem is that, between saying that a filter retains, for example, up to 5mg / m3 of oil mist from a process and attesting that such a filter guarantees that a worker will not be exposed to occupational risks arising from exposure to oil mist there is a huge difference. Each filter has a defined objective. An industrial compressed air filter manufacturer will not certify or guarantee that your filter is for breathable air. He may even say, but he will never testify on letterhead and signed, such insanity.

- A breathing air system must comply with international laws and standards for exposure limits to particulates, vapors and gases that may reach the compressed air system. Industrial compressed air systems, on the other hand, only need to follow the manufacturing and internal construction standards according to ISO 8573.1 & ISO 12500. These standards only provide for the retention of particulates, oil mist and water for industrial applications and not breathable air as can be seen in the article Air Quality Standards ISO 8573.1 & ISO12500. Few companies, even the specialists in breathable air filters, comply with ISO 12500 completely.

- The filter medium also needs to ensure that there will be no proliferation of microorganisms within the meshes. In the case of conventional filters for industrial applications, the filtering medium is not able to prevent this proliferation, and it would not be necessary because it is not intended to do so. It is also worth remembering that, a breathing air system that is not able to prevent water condensates from reaching the breathing air filter system, calls into question its ability to

- guarantee quality breathable air to its users.

- When there is possible contamination in the compressed air system, dedicated breathing air systems need to ensure that aero dispersoids, vapors and gases harmful to health do not reach the user. CO catalyst filters, hydrocarbon retention filters, acid gases, NOx and SOx are specially designed for this purpose and only a few companies in the world have these technologies (just search the internet to be sure). Ordinary filters do not have these characteristics. There are serious companies in the manufacture and development of breathing air systems, but there are also companies that just want to “sell their own fish”. If your application requires breathable air with quality and safety guarantee, look for a specialist company and demand technical documents that prove the efficiency of breathable air filters for your need. Research, discuss and make up your mind only after hearing more than one opinion about breathable air filters.

The know-how of manufacturing breathable air filters is different, the approach is different and norms and standards are different. See some differences between industrial process filters and respirable air filters: