Maximum Length of Breathable Air Hose

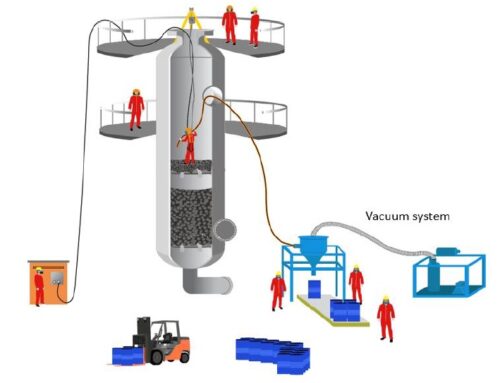

Maximum Length of Breathable Air Hose. There are studies of confined space or in planned work in IDLH atmospheres where the self-contained breathing systems(self contained breathing apparatus, orSCBA)are not sufficient to promote the ideal amount of air sent due to capacity constraints that storage cylinders air impose. Invariably, for such applications the output will be the use of Supplied Air Respirator (SAR), which is nothing more than an external air source with a respirator (air sent).

There are two basic ways of obtaining these resources:

- The first is through the use of cylinder batteries compressed air with large volumes (in the tens of hundreds and hundreds of cubic meters of volume), generally stored at high pressures (1000 <= P <= 3000 psi).

- The second way is through networks compressed air, whether it comes from utility plant air or a dedicated air generation, storage and treatment system for that purpose, that is, providing compressed air with guaranteed quality for workers.

Maximum Length of Breathable Air Hose:

- The maximum length of the combined hose runs must not exceed 91 meters (300 feet);

- The pressure at the inlet connections of the hoses must never exceed the pressure of 8.5 bar (863 kN / m.2, 125 pounds per square inch gage – psi);

Below is table 8, Air-Supply-Line Requirements and Tests, of 42CFR Part 84 Subpart J.149. This table presents the parameters that need to be followed for source systems air respirator

Table 8—Air-Supply-Line Requirements and Tests

|

Specific requirements

|

Requirements for the air-supply lines of the indicated type of supplied-air respirators

|

||

|

Type A

|

Type B

|

Type C

|

|

|

Length of hose

|

Maximum of 91 m. (300 feet), in multiples of 7.6 m. (25 feet)

|

Maximum of 23 m. (75 feet) in multiples of 7.6 m. (25 feet)

|

Maximum of 91 m. (300 feet) in multiples of 7.6 m. (25 feet). It will be permissible for the applicant to supply hose of the approved type of shorter length than 7.6 m. (25 feet) provided it meets the requirements of the part.

|

|

Air flow

|

None

|

None

|

The air-supply hose with air regulating valve or orifice shall permit a flow of not less than 115 liters (4 cubic feet) per minute to tight-fitting and 170 liters (6 cubic feet) per minute to loose-fitting respiratory-inlet coverings through the maximum length of hose for which approval is granted and at the minimum specified air-supply pressure. The maximum flow shall not exceed 425 liters (15 cubic feet) per minute at the maximum specified air-supply pressure with the minimum length of hose for which approval is granted.

|

|

Air flow

|

……do

|

……do

|

The air-supply hose, detachable coupling, and demand valve of the demand class or pressure-demand valve of the pressure-demand class for Type C supplied-air respirators, demand and pressure-demand classes, shall be capable of delivering respirable air at a rate of not less than 115 liters (4 cubic feet) per minute to the respiratory-inlet covering at an inhalation resistance not exceeding 50 millimeters (2 inches) of water-column height measured in the respiratory-inlet covering with any combination of air-supply pressure and length of hose within the applicant’s specified range of pressure and hose length. The air-flow rate and resistance to inhalation shall be measured while the demand or pressure-demand valve is actuated 20 times per minute by a source of intermittent suction. The maximum rate of flow to the respiratory-inlet covering shall not exceed 425 liters (15 cubic feet) per minute under the specified operating conditions.

|

|

Air-regulating valve

|

……do

|

……do

|

If an air-regulating valve is provided, it shall be so designed that it will remain at a specific adjustment, which will not be affected by the ordinary movement of the wearer. The valve must be so constructed that the air supply with the maximum length of hose and at the minimum specified air-supply pressure will not be less than 115 liters (4 cubic feet) of air per minute to tight-fitting and 170 liters (6 cubic feet) of air per minute of loose-fitting respiratory inlet coverings for any adjustment of the valve. If a demand or pressure-demand valve replaces the air-regulating valve, it shall be connected to the air-supply at the maximum air pressure for which approval is sought by means of the minimum length of air-supply hose for which approval is sought. The outlet of the demand or pressure-demand valve shall be connected to a source of intermittent suction so that the demand or pressure-demand valve is actuated approximately 20 times per minute for a total of 100,000 inhalations. To expedite this test, the rate of actuation may be increased if mutually agreeable to the applicant and NIOSH. During this test the valve shall function without failure and without excessive wear of the moving parts. The demand or pressure-demand valve shall not be damaged in any way when subjected at the outlet to a pressure or suction of 25 cm. (10 inches) of water gage for 2 minutes.

|

|

Noncollapsibility

|

The hose shall not collapse or exhibit permanent deformation when a force of 90 kg. (200 pounds) is applied for 5 minutes between 2 planes 7.6 cm. (3 inches) wide on opposite sides of the hose

|

Same as Type A

|

None.

|

|

Nonkinkability

|

None

|

None

|

A 7.6 m. (25 foot) section of the hose will be placed on a horizontal-plane surface and shaped into a one-loop coil with one end of the hose connected to an airflow meter and the other end of the hose supplied with air at the minimum specified supply pressure. The connection shall be in the plane of the loop. The other end of the hose will be pulled tangentially to the loop and in the plane of the loop until the hose straightens. To meet the requirements of this test the loop shall maintain a uniform near-circular shape and ultimately unfold as a spiral, without any localized deformation that decreases the flow of air to less than 90 percent of the flow when the hose is tested while remaining in a straight line.

|

|

Strength of hose and couplings

|

Hose and couplings shall not separate or fail when tested with a pull of 113 kg. (250 pounds) for 5 minutes

|

Same as Type A

|

Hose and couplings shall not exhibit any separation or failure when tested with a pull of 45 kg. (100 pounds) for 5 minutes and when tested by subjecting them to an internal air pressure of 2 times the maximum respirator-supply pressure that is specified by the applicant or at 173 kN/m. 2 (25 pounds per square inch) gage, whichever is higher.

|

|

Tightness

|

No air leakage shall occur when the hose and couplings are joined and the joint(s) are immersed in water and subjected to an internal air pressure of 35 kN/m. 2 (5 pounds per square inch) gage

|

None

|

Leakage of air exceeding 50 cc. per minute at each coupling shall not be permitted when the hose and couplings are joined and are immersed in water, with air flowing through the respirator under a pressure of 173 kN/m. 2 (25 pounds per square inch) gage applied to the inlet end of the air-supply hose, or at twice the maximum respirator-supply pressure that is specified by the applicant, whichever is higher.

|

|

Permeation of hose by gasoline

|

The permeation of the hose by gasoline will be tested by immersing 7.6 m. (25 feet) of hose and one coupling in gasoline, with air flowing through the hose at the rate of 8 liters per minute for 6 hours. The air from the hose shall not contain more than 0.01 percent by volume of gasoline vapor at the end of the test

|

Same as for Type A

|

Same as for Type A, except the test period shall be 1 hour.

|

|

Detachable coupling

|

None

|

None

|

A hand-operated detachable coupling by which the wearer can readily attach or detach the connecting hose shall be provided at a convenient location. This coupling shall be durable, remain connected under all conditions of normal respirator use, and meet the prescribed tests for strength and tightness of hose and couplings.

|