Carbon Monoxide in Air Compressors

Carbon Monoxide in Air Compressors. The process of air compression and the formation of carbon monoxide (CO)

Under normal conditions of use, air compressors are unlikely to generate carbon monoxide, or once the working temperatures and lubricant characteristics are up to date.

The problem occurs every time the compressors exceed their working temperature, or even if the quality of the lubricant is questionable or with the properties expired. In this case, if there is an overheating in the compression head (or any other mechanism responsible for the compression) together with the lubricating oil and little oxygen from the process, it can generate carbon monoxide.

Carbon is oxidized by combining with oxygen at a higher temperature to form oxides, such as carbon monoxide (CO) and carbon dioxide(CO2). Carbon monoxide is formed when combustion is incomplete, that is, low in oxygen. Therefore:

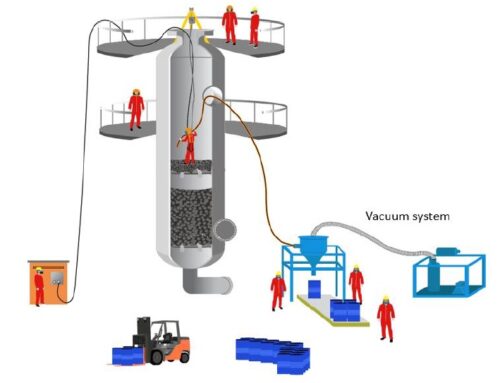

CO is present in car exhaust (when there is incomplete combustion), volcanic gases, chimney gases, etc. Below is the diagram of the air compressor (O2 or CO2) and the formation of CO from the lean mixture.

How to avoid the risk of carbon monoxide (CO)

The Breathe developed a low cost CO monitor and ideal pair meet applications where it is used air compressed breathing for occupational purposes.

The XAR-LC is connected to a branch of the compressed air line and thus ensures in real time that the CO concentration does not reach or exceed occupational limits. The ABNT NBR 12543: 2017 standard, for example, determines that this limit does not exceed 10 ppm. The XAR-LC has an LED interface that indicates the level of CO in the air line (bargraph) and when the limit is reached, an audible and visual alarm is emitted to inform the situation.

The device also has a remote alarm trigger output that can turn off a compressor or even connect a siren to a remote visual alarm. The XAR-LC is also perfect to meet the new revision PPR of Fundacentro’s which requires the use of a CO monitor in the air network when using breathable compressed air for occupational purposes.