Breathable Air Compressors. Breathable Air Grade D

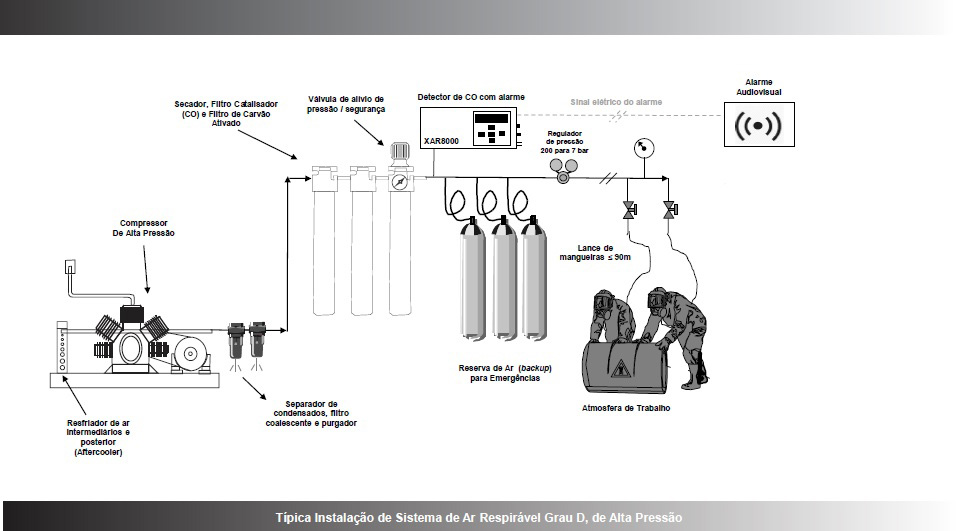

Breathable Air Compressors. Breathable Air Grade D – High Pressure System. Breathable Air Compressors. OSHA does not specify or make any reservations regarding any type of compressor that will be used for the purpose of producing breathable air. Oil-lubricated or exempted compressors can be used as breathable air compressors.

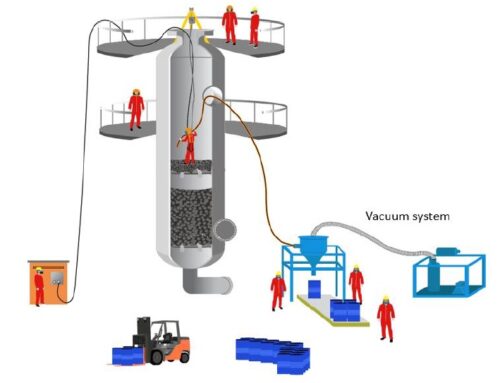

In many cases, air compressors from industrial plants or utility sectors can be used safely as sources of breathable air as long as care is taken with regard to filtration, purification and air quality control. These items, by the way, are requirements of the OSHA standard. Regardless of the type of compressor, the air inlet must be located in order to minimize the entry of contaminants. It is generally easier to meet these requirements, if the inlet is located outside the plant, away from exhaust areas of combustion engines, exhaust chimneys, exhaust and ventilation nozzles or other possible sources of contamination that may be present.

These are OSHA requirements for the line and the adsorbent filters to perform necessary to achieve grade D, or better, air quality. The specific sorbent and filters needed to meet this requirement are largely due to the quality of the air produced, or designed in a compressor, in particular. Essentially, the systems available to improve air quality fall into two categories:

Filtration Systems

This type of system removes contaminants from aerosols (mainly by water and oil vapors). They are generally made up of one or more filter elements. It is common to find one of the activated carbon filters to remove traces of organic vapors, hydrocarbons and / or odors. Filtration system does not remove carbon monoxide or other gaseous contaminants, nor does it reduce the dew point.

Purification

Purification systems are sets of filters used to remove aerosol contaminants and specific contaminating gases, including carbon monoxide. They may or may not include an air dryer to reduce the dew point,catalysts carbon monoxide, filters or filtration systems as simple as coalescent filters and screen filters or as complex as desired, such as molecular sieves, filters by adsorption and catalyst filters to obtain air quality at the outlet.

All purification systems have limitations in terms of the ability to retain specific contaminants, concentrations and time of exposure of these filters to contaminants. No system can always guarantee grade D, or better, air quality in the criteria required by the OSHA standard in the ‘D’ grade.

The OSHA regulation requires that the adsorbent or filters present must be kept under conditions specified by the manufacturer and also replaced according to manufacturers’ instructions.